Wood Thermal Modified System (SNH Bimetallic Cylinder)

- Description

Product Description

XNH wood thermal modified system is developed by Institute of Drying Technology of Nanjing Forestry and Jiangsu XINAN Wood Drying Systems Co., LTD based on careful study of existing high temperature heat-treated equipment both in China and abroad. The equipment is safe and reliable, and can improve defects of the wood, so rare wood resources could be utilized effectively and fully developed as solid wood products.

Advantages of XNH Bimetallic Cylinder for Wood Thermal Modification

- Controlling instrument made in Germany to ensure precise and reliable control

- Circulating device to make thermal uniform

- Temperature can be adjusted between 160℃ and 220℃ according to the requirement

- Two sets of pressure control system to ensure equipment running safely

- Bimetallic (Carbon steel and stainless steel) shell with economical efficiency, durability and intensity

- Flexible and suitable for production of small batch

Main Technology Coefficient of XNH Bimetallic Cylinder

Model | Capacity (m3) | Kiln Dimension (m) | Dimension of stack (m) |

XNH-CS4 | 4 | Ø 2.2×4 | 4×1.2×1.5 |

XNH-CS6 | 6 | Ø2.2×6 | 6×1.2×1.5 |

XNH-CS8 | 8 | Ø 2.2×12.2 | 8×1.2×1.5 |

XNH-CS15 | 15 | Ø 2.8×8.2 | 8×1.8×2.0 |

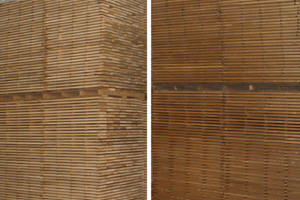

Before and after treatment

The color of heat treated wood at different treatment temperatures

Related Products

Read MoreQuick View

Read MoreQuick ViewWood Thermal Modified System (All-aluminum)

- Developed by XINAN and Institute of Drying Technology of Nanjing Forestry University

- The equipment can improve the function of the wood to fully develop as wood products.

- XNH wood thermal modified system has two structures: all-aluminum assembled kiln and carbon steel and stainless steel composite cylinder.

Read MoreQuick View

Read MoreQuick View

Read MoreQuick ViewHeat Pump Heating Wood Drying Kiln

■ Automatic and Semi-automatic Control system

■ All-aluminum alloy or Masonry kiln housing

■ new technology of heat pump heating without pollution

■ increase 2-4 times’ thermal efficiency compared to electric heating

Read MoreQuick View