Read MoreQuick View

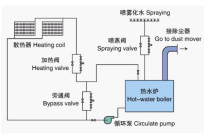

Read MoreQuick ViewHot Water Boiler with Wood Waste as Fuel

- This system is safe and reliable, and features energy and capital saving, coolant and water saving, and low running cost.

- It has wide usage, high thermal efficiency, generates zero pollution and keeps temperature stable.

- The system features hot water circulating system and automatic screw transporting system.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewAutomatic Wood Drying Control System (Imported)

- uses HOLZMEISTER, which supports individual programs and is very stable

- Heating, conditional venting and the running direction of the fan are automatically controlled

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewAutomatic Wood Drying Control System (XINAN)

- high definition LED screen

- multiple human-machine interface, automatic control of each actuator in the kiln

- memory after power failure and alarm of abnormal state

Read MoreQuick View

Read MoreQuick View

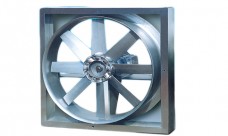

Read MoreQuick ViewCirculating Fan

- The circulating fan has size 6 (Φ 600mm), 8(Φ 800mm), and 10(Φ 1000mm).

- The circulating fan is made of aluminum alloy adopting technology from Germany.

- The fans features scientific dynamic and static balance tests, big air volume and high air pressure, and can run clockwise and counter-clockwise.

- The motor is waterproof, high temperature-resistant and exempted from customs check.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewHeating Coil

- The coil uses stainless steel and aluminum bimetallic ribbed pipes.

- The coil is light weight, less resistant to the steam, anticorrosive and high thermal efficiency.

- It is also reasonably designed, fast and easy to install.

Read MoreQuick View

Read MoreQuick View

Read MoreQuick ViewElectric Valve

- The electric valve is made in Japan, Italy, and Germany.

- It features small volume, high reliability, accurate control of temperature, and is efficient in heat-controlling and energy saving.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewTemperature, relative humidity and moisture content

- Six pairs of moisture content probes, 2 or more pairs of temperature and 2 EMC probes in every kiln.

- The probes are made of stainless steel and joints are imported to ensure accurate measurement.

- Signals are transported through special high temperature-resistant cables.

Read MoreQuick View Read MoreQuick View

Read MoreQuick ViewVent Motor

- The motor can be turned 0 to 90 degrees based on humidity inside in the kiln.

- Automatic and manual operation can be switch outside of the kiln.

- Made in Korea or Switzerland with superior performance and high reliability. The twisting torque can reach 16NM.

Read MoreQuick View

© Copyright 2015. All Rights Reserved.